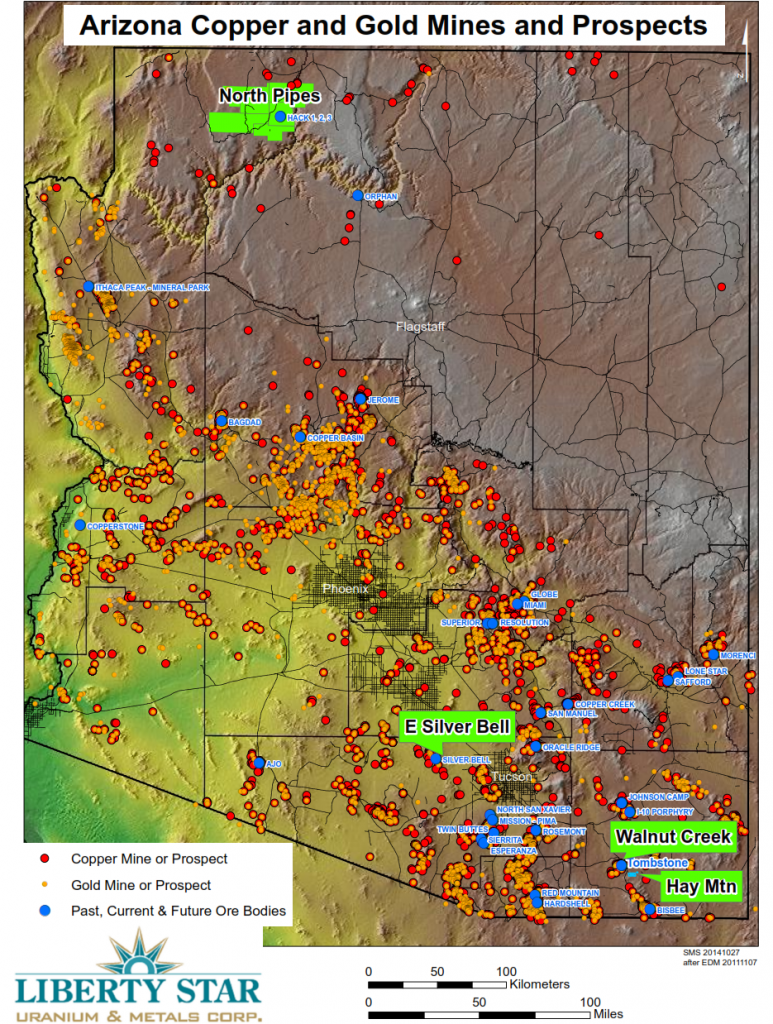

States Liberty Star’s CEO/Chief Geologist James A. Briscoe: “The Company plans to bring in our contracted diamond core drill, Titan Drilling’s R-40, to the Hay Mountain Project and complete Phase 1 of the exploration drilling including analysis of the mineralization located on our mineral property. Until this drilling of up to 12 holes and perhaps more, we cannot confirm what is causing certain anomalies, which are classic indicators of known porphyry copper mineralization. By comparison to similar nearby porphyry copper systems which are currently being mined or have been mined in the past, which include Bisbee approximately 15 miles to the south, Rosemont — about 50 miles to the west, and the Mission-Pima ore body about 60 miles to west, Johnson Camp and the I-10 Porphyry (aka the Gunnison in-situ leach by Excelsior about 30 to 35 miles north and the Courtland-Gleeson skarn about 9 miles northeast all of which are sediment hosted skarn mineral bodies that are in the same rock types as those which underlie the Hay Mountain Super Project. The same types of mineral bodies occur in Mexico about 50 miles southwest at the Cananea (now Buena Vista) and about 60 miles southeast at the La Caridad mine. These types of altered sediment hosted mineral systems (along with disseminated mineralization in porphyry intrusive rocks) contain higher than ordinary copper-moly, lead, zinc, silver & gold ore bodies. Bisbee for example, when first exposed by mining, encountered copper values between 5% and 30% (Ransome, F.L., 1904, Geology of the Bisbee Quadrangle, Arizona US Geological Survey, Professional Paper 21, 168 p.). While we do not know until drilling whether mineralized rock of this grade will be located in places at Hay Mountain, there is no reason that this is not a possibility. Further, the discovery of the Pima mine, which is now part of the Mission-Pima ore body, was a blind (unexposed) mineral body, like Hay Mountain. Aside from favorable altered rock exposures some distance away, Pima was discovered by ground magnetic and electromagnetic anomalies, followed by initial drilling. These geophysical techniques are like the ZTEM that we have run by helicopter borne surveys (which did not exist in 1948) but made more powerful and sensitive by computer technology. The discovery at Pima was made by drilling the anomaly(s) which is what we are going to do at Hay Mountain. This is exactly what we are planning with our Phase 1 program.”

The Company intends to raise capital privately to fund the Phase I operation.

As part of the Phase 1 process, drill core will be immediately processed at the Company’s field camp site near the drilling area in the normal way, including washing, high resolution digital photography, saw splitting with diamond saws, bagging ½ the split core for assay and sequestering that split core in a secure trailer under lock and key, then shipping that core, under chain of custody to a Tucson-based certified assay lab for crushing, grinding to minus 80 mesh and splitting into an assay aliquots and then shipping those to the certified assay lab for multi-element assays. Adds Mr. Briscoe: “The turnaround we believe will be very rapid. Duplicate, blanks and standard samples will be inserted into the sample stream for precision and accuracy test purposes.”

More details of the Phase 1 process include:

- Samples will be taken at appropriate intervals, directed and/or performed by a drill site geologist from the SRU (Sample Recovery Unit) adjacent to the drill (NR193). Drill cuttings samples over appropriate intervals will be analyzed using the Niton XRF for analysis through-out the length of the hole.

- The archived split core will be re-photographed with the flat, sawed side up, logged by a highly qualified geologist and will be re-assayed using the Niton XRF, logged with magnetic and electrical susceptibility meter(s), and a gamma ray spectrometer which will give us quantitative amounts of uranium, thorium and potassium and then placed in semi-permanent core storage also under lock and key. Permanent storage will be at The Companies ware house in Tucson, Arizona about 100 miles distant.

- Progress news releases will be sent out as rapidly as is practical. Geologic-mineralogical core logging will be done on laptop computers, using core-logging software, and cross sections constructed as data is compiled — all of this being done on site by two shifts of highly qualified geologists. Over all supervision will be by James Briscoe, Registered Professional Geologist who will be based at the drill site.

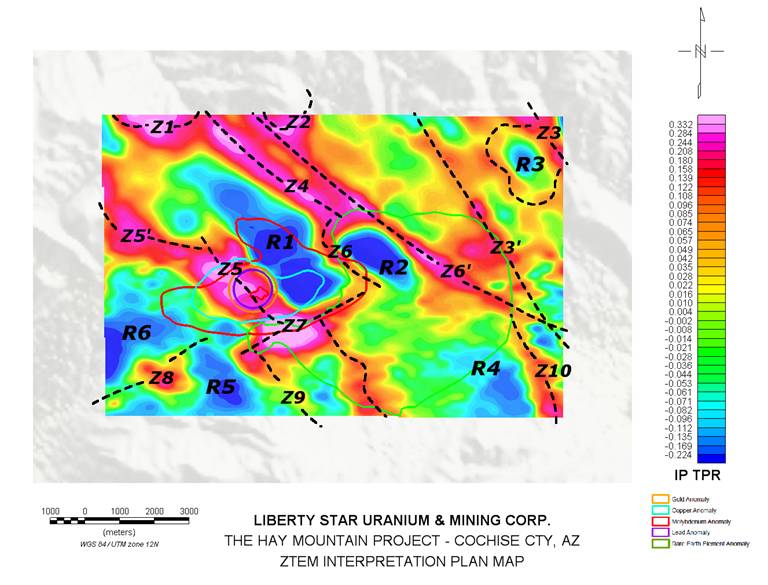

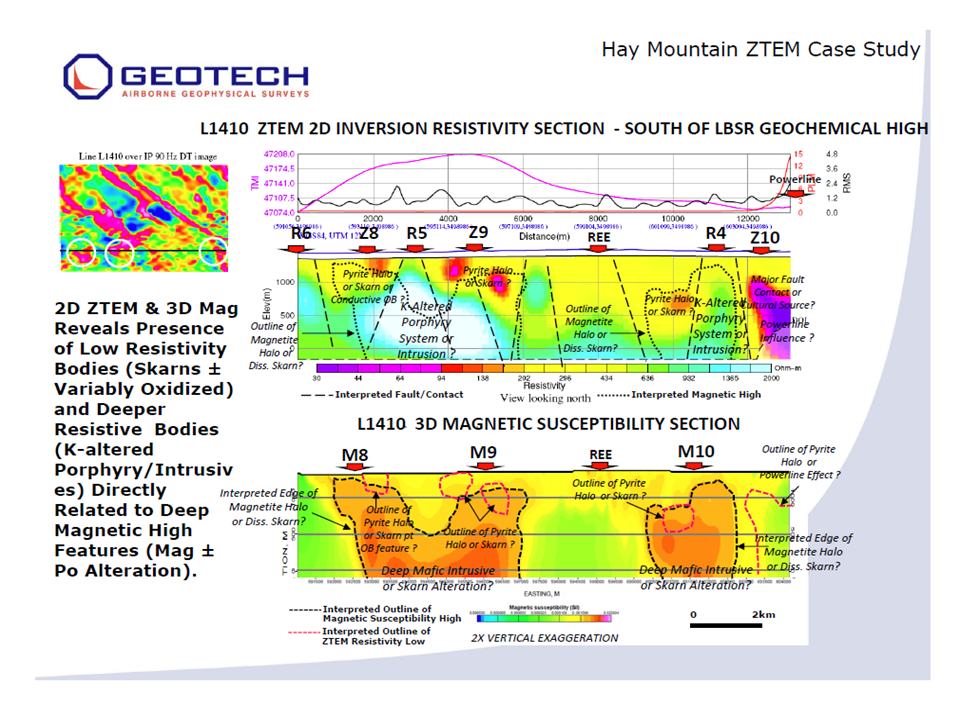

Liberty Star – Hay Mountain ZTEM Case Study – ZTEM 2D Inversion Resistivity Section and #D Magnetic Susceptibility Section

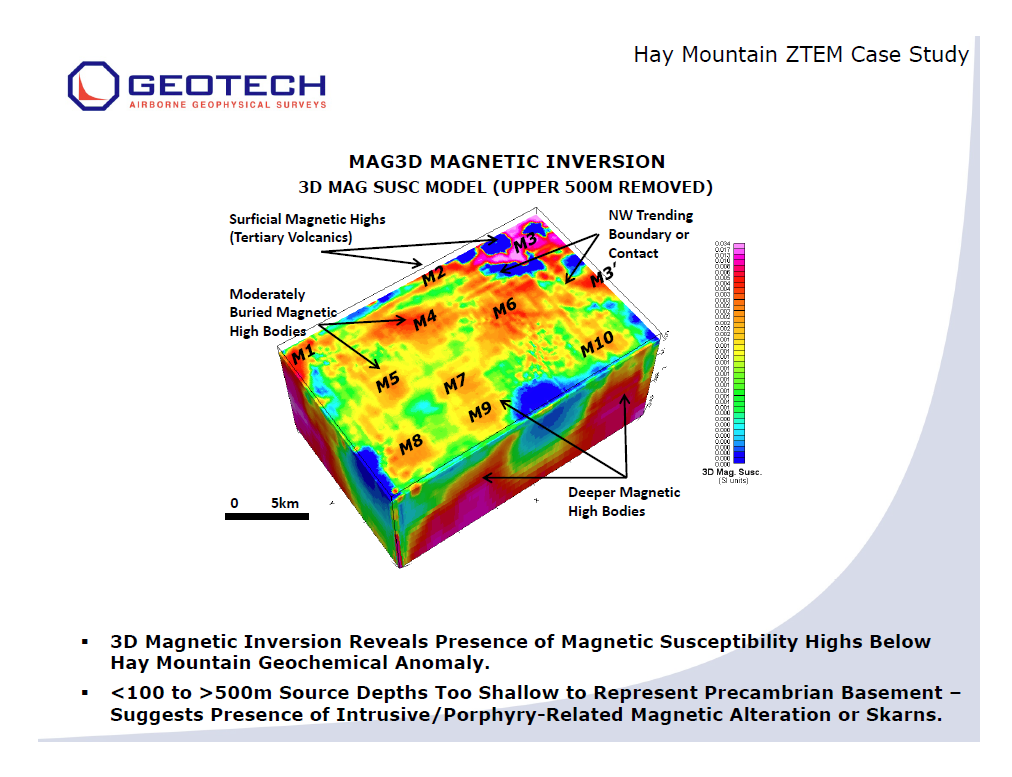

3D Magnetic Inversion Reveals Presence of Magnetic Susceptibility Highs Below Hay Mountain Geochemical Anomoly

See Liberty Star’s collection of ZTEM and Geotech presentations

ZTEM – “Mineral exploration using the Z-TEM or Z-Axis Tipper Electromagnetics, an airborne AFMAG system, has been guided by numerical modeling of the target types. Numerical modeling is used to plan the survey in terms of survey line spacing, survey height, and expected signatures of the targets. Knowing the Z-TEM response of a deposit of the type that is being explored for, aids in the interpretation of the results. Numerical modeling has demonstrated that the Z-TEM system is ideally suited for large, deep deposits of low to high resistivity contrasts such as porphyry copper and SEDEX deposits.” Microsoft PowerPoint & PDF Presentations courtesy of: Geotech Ltd

Timeline

ZTEM Overflight of Liberty Star’s Hay Mountain Property to Begin First Week of June

Liberty Star Hay Mountain Update: ZTEM Survey Overflight Completed

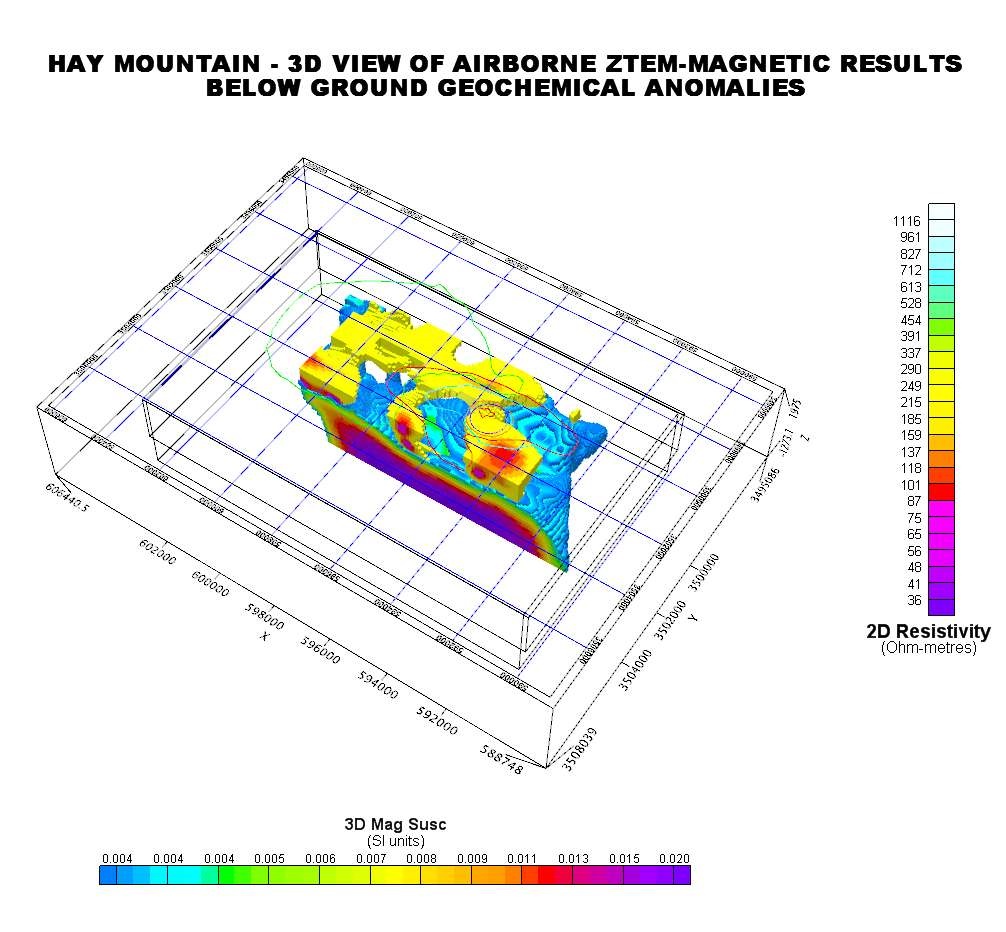

Hay Mountain – 3D View of Airborne ZTEM-Magnetic Results Below Ground Geochemical Anomalies – Northeast

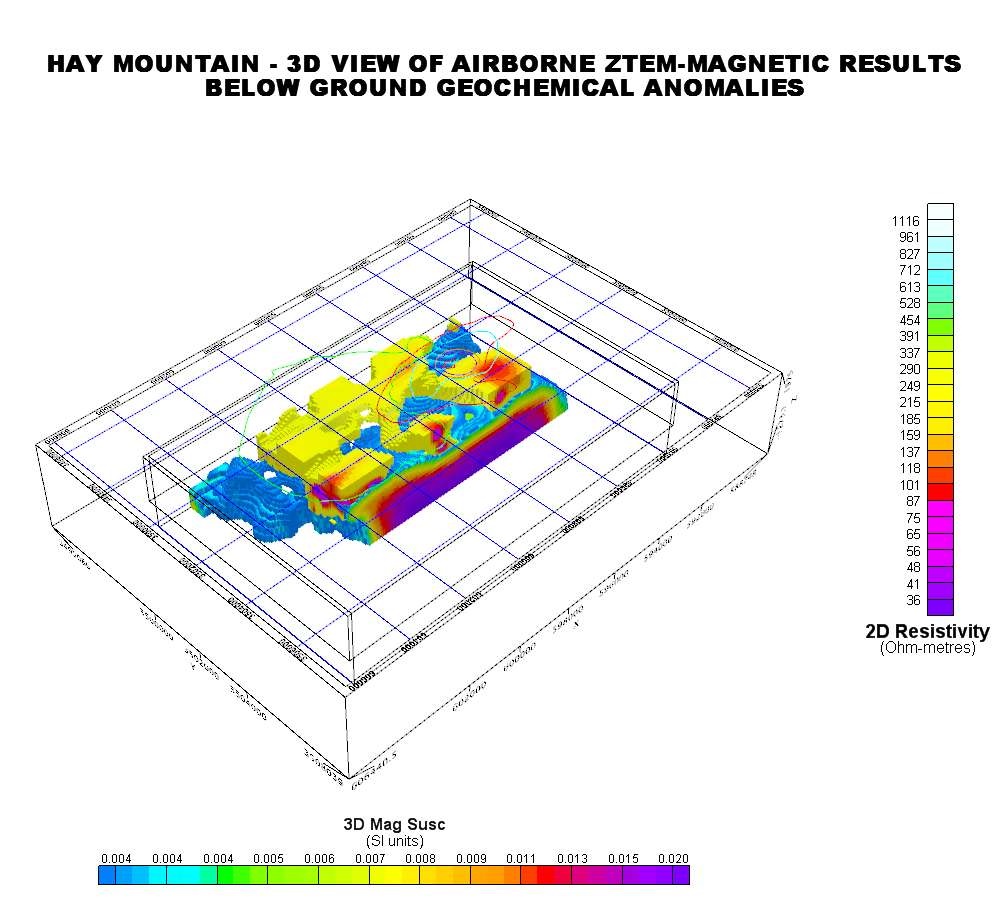

Hay Mountain – 3D View of Airborne ZTEM-Magnetic Results Below Ground Geochemical Anomalies – Northwest

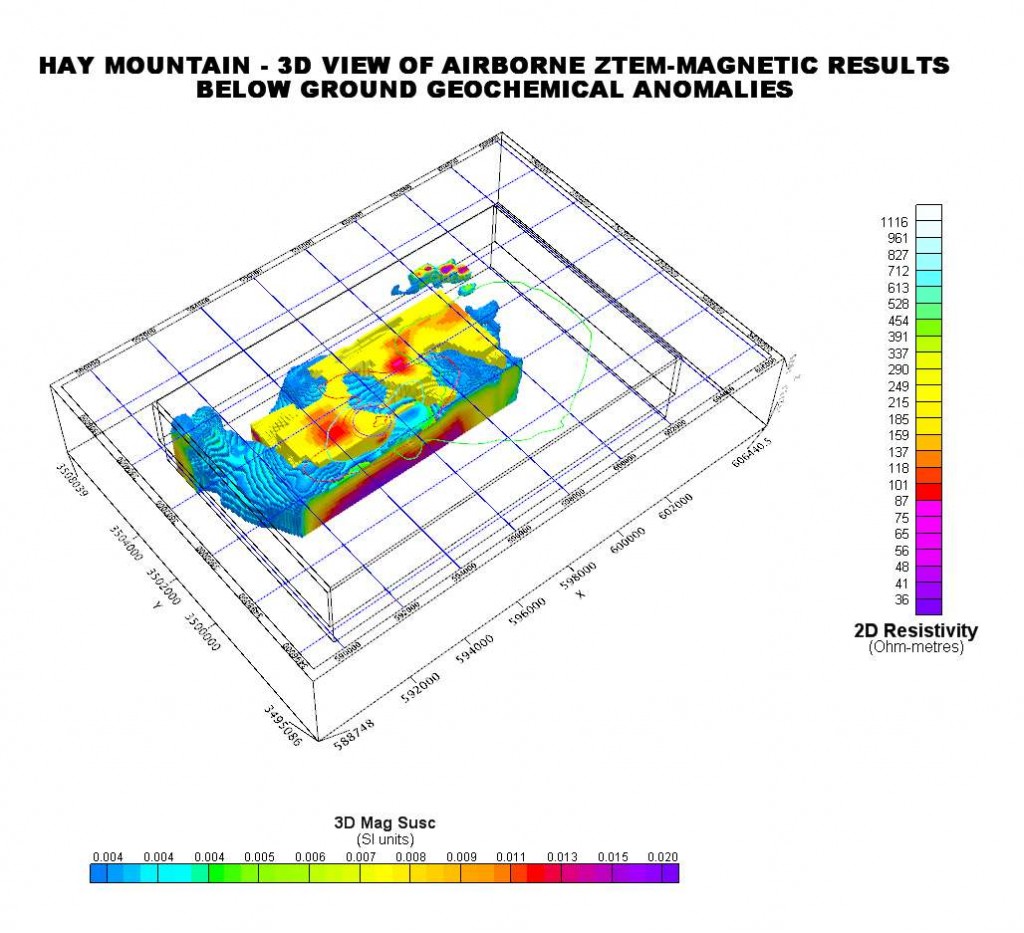

Hay Mountain – 3D View of Airborne ZTEM-Magnetic Results Below Ground Geochemical Anomalies – Southwest

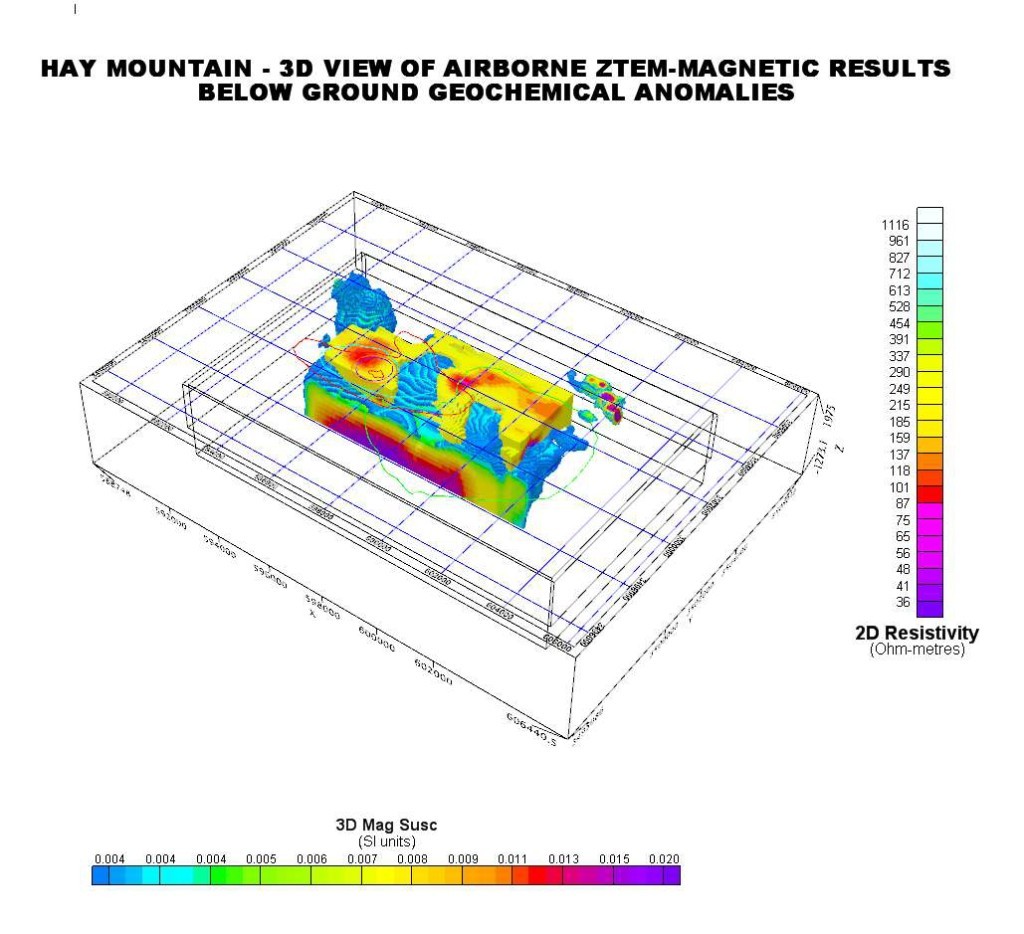

Hay Mountain – 3D View of Airborne ZTEM-Magnetic Results Below Ground Geochemical Anomalies – Southeast