Published: October 15, 2018

Examples of gossan from the Toby Prospect (left) and Charlie Prospect (right)

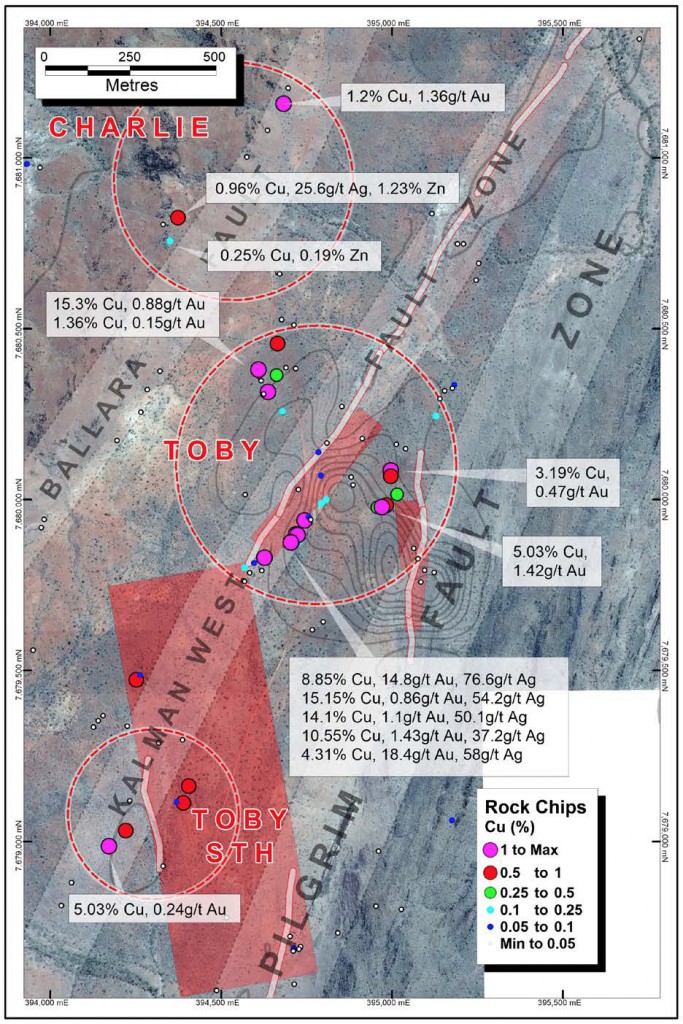

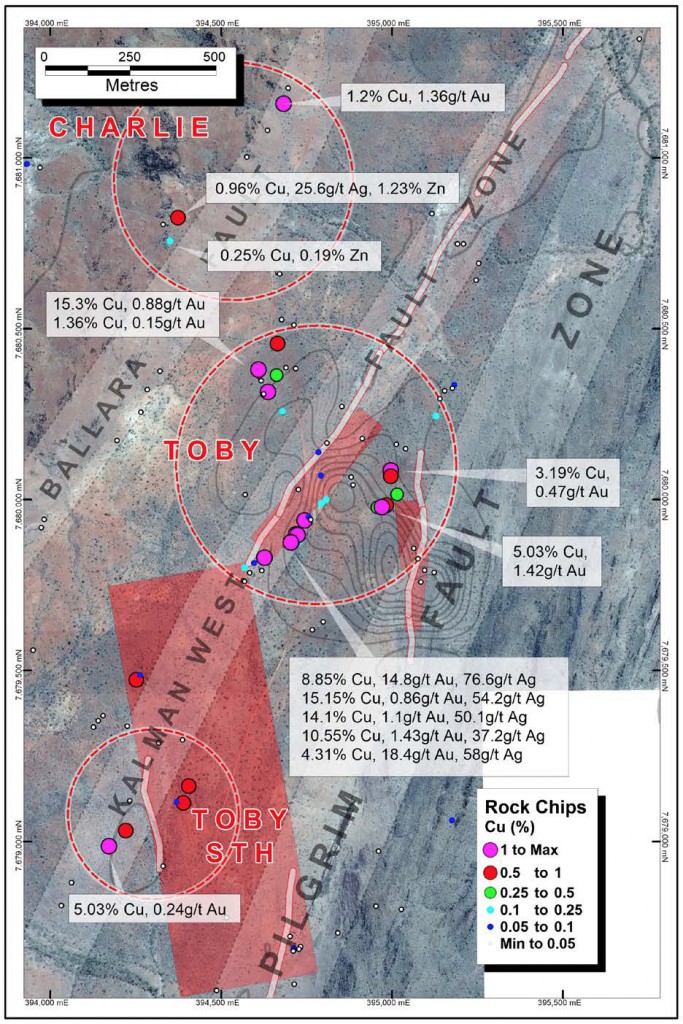

- High grade rock chips with individual peak grades of up to 18.4g/t Au, 76g/t Ag and 15.15% Cu returned from the new Toby prospect located 8km north of the Kalman deposit.

- The prospect was located by Hammer personnel investigating a group of VTEM conductors near the intersection of the Ballara, Kalman West and Pilgrim Faults.

- Several zones of outcropping gossan over a strike length of 400m were found in the area which is mostly obscured by thin soil cover.

- Subsequent follow-up prospecting of a smaller VTEM anomaly 500m to the northwest of Toby has identified a red-rock altered breccia zone up to 40m in width coincident with the anomaly.

- The initial samples from the (Charlie) Prospect obtained individual peak grades of up to 1.36g/t Au, 25.6g/t Ag, 1.2% Cu and 1.23% Zn.

- Follow-up sampling of and mapping of Toby and Charlie is underway with results expected soon.

- As announced to the ASX a sub audio magnetics (“SAM”) survey and reverse circulation drilling program is scheduled for Perentie for October-November period. (Refer ASX announcement 11 October 2016.)

Hammer’s Executive Chairman said: “Diligent field work is continuing to find new zones of untested mineralisation in this highly mineralised terrain in NW Queensland. The location of these prospects along strike from Hammer’s Kalman deposit is encouraging and we look forward to bringing shareholders more news from Toby and Perentie in coming weeks.”

TOBY AND CHARLIE PROSPECTS

The Toby prospect is located close to the intersection of the Ballara, Kalman West and Pilgrim Faults, a zone of major structural complexity on the eastern margin of the Mt Philp Breccia and west of the Pilgrim Fault. The prospects are approximately 8km north of Hammer’s Kalman Cu-Mo-Au-Re deposit. The area was covered by a 2016 VTEM survey (refer ASX announcement 22 December 2016) which at Toby outlined a significant conductive zone and a smaller anomalous VTEM anomaly called Charlie 600m to the northwest. Modelling of these conductors delineated several conductive plates.

Recent reconnaissance rock chip sampling at Toby has obtained individual peak grades of up to 18.4g/t Au, 76g/t Ag and 15.15% Cu. Refer to Table 1 for a full list of results.

The Charlie prospect is close to the eastern margin of the Mt Philp Breccia and the interpreted position of the Ballara Fault. Reconnaissance sampling identified a zone of gossanous red rock breccia up to 40m thick. First pass rock chip sampling over the area obtained individual peak grades of up to 1.36g/t Au, 25.6g/t Ag, 1.2% Cu and 1.23% Zn.

More detailed follow-up sampling is underway with results expected in the near future.

For further information contact:

Russell Davis | Executive Chairman

T: +61 8 6369 1195

info@hammermetals.com.au

www.hammermetals.com.au

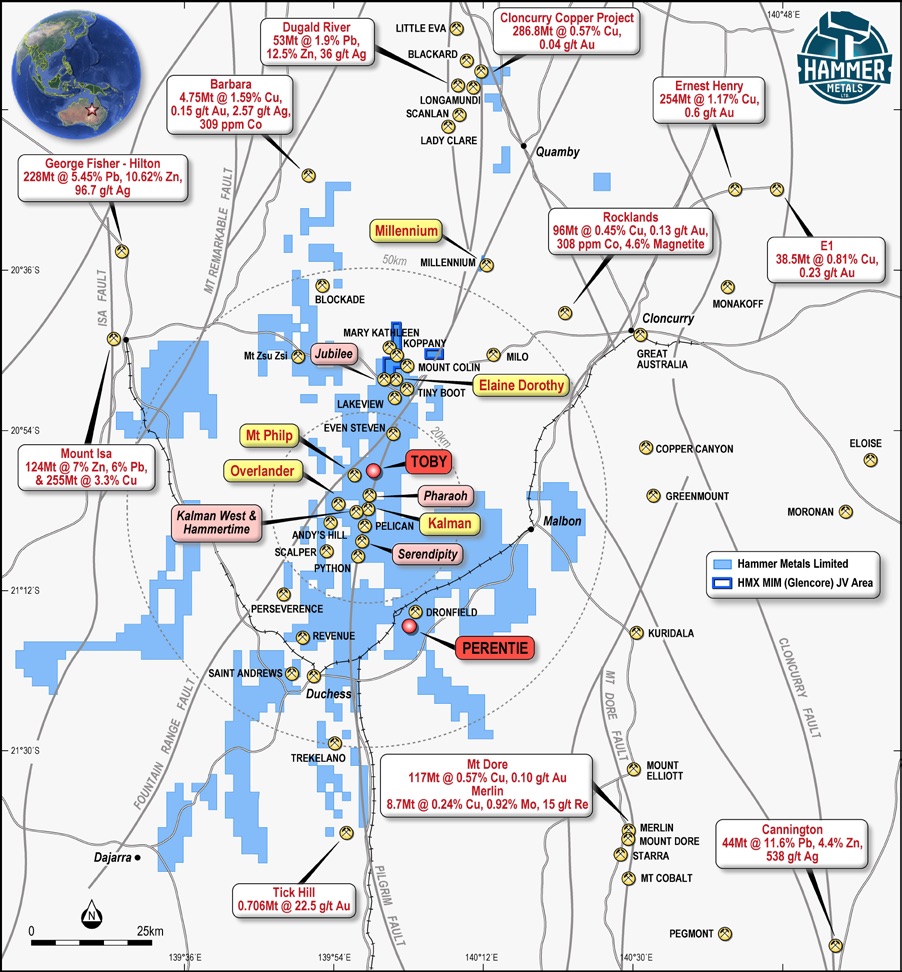

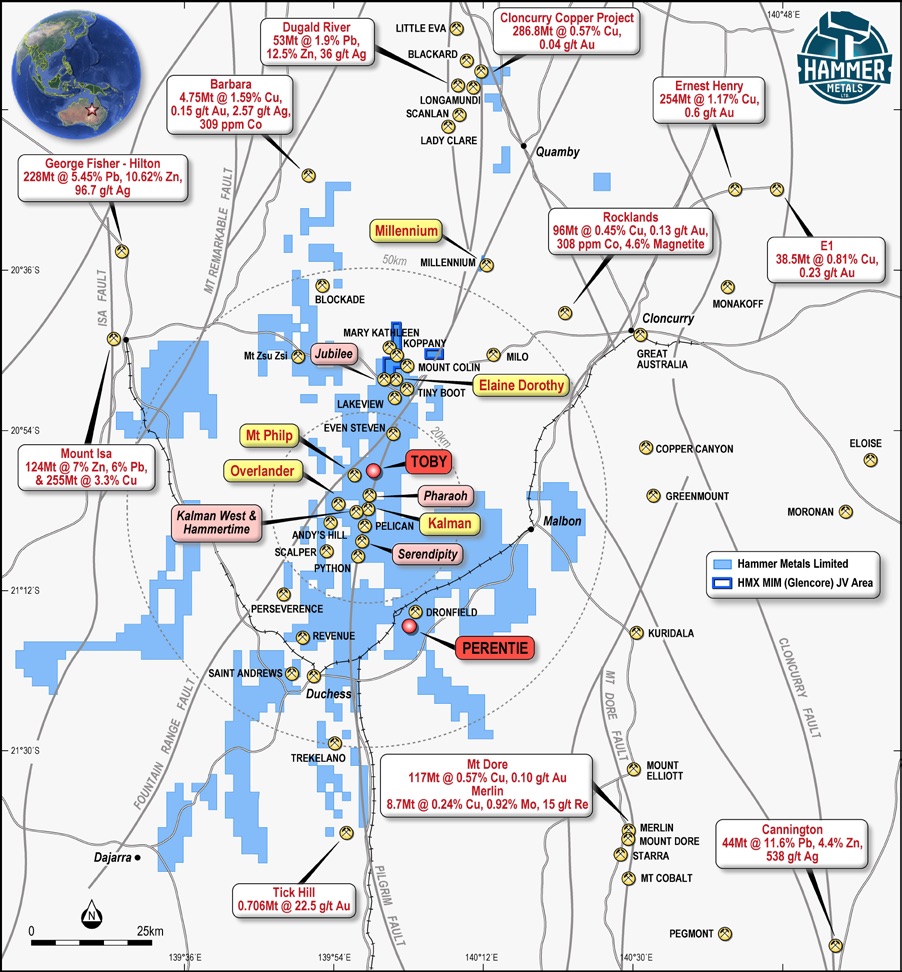

Hammer Metals Limited (ASX: HMX) holds a strategic tenement position covering approximately 3000km2 within the Mount Isa mining district, with 100% interests in the Kalman (Cu-Au-Mo-Re) deposit, the Overlander North and Overlander South (Cu-Co) deposits and the Elaine-Dorothy (Cu-Au) deposit. Hammer also has a 75% interest in the Millennium (Cu-Co-Au) deposit and a 51% interest in the emerging Jubilee (Cu-Au) project. Hammer is an active mineral explorer, focused on discovering large copper-gold deposits of the Ernest Henry style and has a range of prospective targets at various stages of testing.

Competent Person’s Statement:

Exploration Results

The information in this report as it relates to exploration results and geology was compiled by Mr. Mark Whittle, who is a Member of the AusIMM and a consultant to the Company. Mr.Whittle who is a shareholder and option-holder, has sufficient experience which is relevant to the style of mineralisation and type of deposit under consideration and to the activity which he is undertaking to qualify as a Competent Person as defined in the 2012 Edition of the ‘Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves’. Mr. Whittle consents to the inclusion in the report of the matters based on the information in the form and context in which it appears.

Toby and Charlie Prospects showing the location of elevated rock chip samples (current and previously reported) in relation to VTEM conductivity contours, target axes and modelled plates.

Table 1 – Rock chips from Toby and Charlie Prospects (Samples taken from both mineralised and unmineralised zones)

| Area |

Sample |

E_GDA (1) |

N_GDA (1) |

RL (2) |

Au (g/t) |

Ag(g/t) |

Cu(%) |

Zn (%) |

| TOBY |

MW6_36 |

394284 |

7680325 |

500 |

-0.01 |

0.00 |

0.00 |

0.00 |

| MW6_37 |

394265 |

7680259 |

500 |

0.02 |

0.00 |

0.01 |

0.00 |

| MW6_38 |

394195 |

7680176 |

500 |

0.01 |

0.00 |

0.01 |

0.00 |

| MW6_43 |

394565 |

7679766 |

500 |

-0.01 |

0.00 |

0.00 |

0.00 |

| CW |

394724 |

7679902 |

400 |

14.80 |

76.60 |

8.85 |

0.00 |

| E36975 |

394762 |

7679944 |

350 |

0.02 |

0.60 |

0.04 |

0.00 |

| E36976 |

394723 |

7679899 |

343 |

1.43 |

37.20 |

10.55 |

0.00 |

| E36977 |

394703 |

7679877 |

346 |

18.40 |

58.00 |

4.31 |

0.01 |

| E36978 |

394263 |

7679486 |

360 |

0.02 |

0.10 |

0.07 |

0.00 |

| E36979 |

394793 |

7679988 |

352 |

0.03 |

0.80 |

0.13 |

0.00 |

| E36980 |

394808 |

7679999 |

352 |

0.06 |

0.60 |

0.10 |

0.00 |

| E36981 |

394793 |

7680070 |

352 |

0.01 |

0.30 |

0.05 |

0.01 |

| E36982 |

394785 |

7680138 |

353 |

-0.01 |

0.10 |

0.05 |

0.00 |

| E36983 |

394853 |

7680276 |

358 |

-0.01 |

0.10 |

0.02 |

0.00 |

| E37009 |

394957 |

7679980 |

352 |

0.16 |

0.50 |

0.41 |

0.00 |

| E37010 |

394970 |

7679981 |

351 |

1.42 |

2.30 |

5.03 |

0.00 |

| E37011 |

394886 |

7680046 |

351 |

0.01 |

0.10 |

0.02 |

0.00 |

| MJB001 |

394664 |

7680459 |

357 |

0.28 |

0.40 |

0.70 |

0.00 |

| MJB002 |

394713 |

7680514 |

360 |

0.03 |

-0.20 |

0.01 |

0.00 |

| MJB004 |

394640 |

7679843 |

350 |

-0.01 |

-0.20 |

0.01 |

0.00 |

| MJB005 |

394637 |

7679841 |

349 |

0.01 |

-0.20 |

0.00 |

0.00 |

| MJB006 |

394631 |

7679832 |

350 |

0.02 |

-0.20 |

0.01 |

0.00 |

| MJB007 |

394626 |

7679833 |

365 |

0.86 |

54.20 |

15.15 |

0.01 |

| MJB008 |

394619 |

7679795 |

340 |

0.04 |

-0.20 |

0.01 |

0.00 |

| MJB009 |

394597 |

7679814 |

351 |

-0.01 |

-0.20 |

0.09 |

0.01 |

| MJB010 |

394569 |

7679800 |

351 |

-0.01 |

0.70 |

0.16 |

0.00 |

| MJB011 |

394583 |

7679789 |

368 |

0.02 |

-0.20 |

0.00 |

0.00 |

| MJB012 |

394568 |

7679764 |

351 |

-0.01 |

-0.20 |

0.00 |

0.00 |

| MJB013 |

394705 |

7679879 |

361 |

1.40 |

33.10 |

2.70 |

0.01 |

| MJB014 |

394718 |

7679901 |

353 |

1.10 |

50.10 |

14.10 |

0.00 |

| MJB015 |

394718 |

7679897 |

352 |

0.01 |

0.60 |

0.02 |

0.00 |

| MJB016 |

394733 |

7679911 |

364 |

0.02 |

0.30 |

0.03 |

0.00 |

| MJB017 |

394729 |

7679876 |

360 |

0.01 |

0.50 |

0.12 |

0.00 |

| MJB018 |

394743 |

7679942 |

378 |

0.77 |

4.10 |

2.09 |

0.00 |

| MJB019 |

394756 |

7679949 |

352 |

0.03 |

0.20 |

0.08 |

0.00 |

| MJB020 |

395064 |

7679861 |

355 |

-0.01 |

-0.20 |

0.02 |

0.00 |

| MJB021 |

395076 |

7679830 |

353 |

0.01 |

-0.20 |

0.01 |

0.01 |

| MJB022 |

395095 |

7679796 |

355 |

0.08 |

0.50 |

0.01 |

0.00 |

| MJB023 |

395123 |

7679790 |

359 |

-0.01 |

-0.20 |

0.00 |

0.00 |

| CHARLIE |

E36909 |

394696 |

7681207 |

364 |

-0.01 |

0.02 |

0.00 |

0.00 |

| E36911 |

394635 |

7681084 |

372 |

-0.01 |

0.01 |

0.00 |

0.00 |

| E36913 |

394373 |

7680828 |

389 |

0.01 |

25.60 |

0.96 |

1.23 |

| E36914 |

394330 |

7680808 |

403 |

-0.01 |

0.06 |

0.00 |

0.00 |

| E36910 |

394682 |

7681161 |

359 |

1.36 |

1.25 |

1.20 |

0.00 |

| E36912 |

394351 |

7680756 |

391 |

0.01 |

9.79 |

0.25 |

0.19 |

| E37012 |

394666 |

7680667 |

355 |

-0.01 |

0.01 |

0.00 |

0.00 |

| E37013 |

394671 |

7680664 |

355 |

-0.01 |

-0.01 |

0.01 |

0.00 |

Note

(1) – Locations relative to GDA94 Zone 54

(2) – RL Assigned from GPS – Will be corrected utilising most accurate DEM data

Hammer Metals Mount Isa Project area showing the location of the Toby Prospect

JORC Code, 2012 Edition

Table 1 report – Exploration Update

- This table is to accompany an ASX release updating the market with results as they are reported from the exploration activities conducted by Hammer Metals Limited on the Toby and Charlie Prospects.

Section 1 Sampling Techniques and Data

(Criteria in this section apply to all succeeding sections in this information release.)

| Criteria |

JORC Code explanation |

Commentary |

| Sampling techniques |

- Nature and quality of sampling (eg cut channels, random chips, or specific specialised industry standard measurement tools appropriate to the minerals under investigation, such as down hole gamma sondes, or handheld XRF instruments, etc). These examples should not be taken as limiting the broad meaning of sampling.

- Include reference to measures taken to ensure sample representivity and the appropriate calibration of any measurement tools or systems used.

- Aspects of the determination of mineralisation that are Material to the Public Report.

- In cases where ‘industry standard’ work has been done this would be relatively simple (eg ‘reverse circulation drilling was used to obtain 1 m samples from which 3 kg was pulverised to produce a 30 g charge for fire assay’). In other cases, more explanation may be required, such as where there is coarse gold that has inherent sampling problems. Unusual commodities or mineralisation types (eg submarine nodules) may warrant disclosure of detailed information.

|

- Reconnaissance rock chip sampling is reported in this release. The nature of sampling is termed grab sampling. Samples are collected across the strike of the zone of mineralisation, but sampling is not via the continuous chip method.

- This style of sampling enables general grade and metal content to be established however it is not as representative as continuous chip sampling, costean sampling or drilling to establish grade across a structure.

- Samples tabulated in this release have been taken from both mineralised and unmineralised material. This is a common practice to determine background element concentrations in an area.

|

| Drilling techniques |

- Drill type (eg core, reverse circulation, open-hole hammer, rotary air blast, auger, Bangka, sonic, etc) and details (eg core diameter, triple or standard tube, depth of diamond tails, face- sampling bit or other type, whether core is oriented and if so, by what method, etc).

|

- No drilling has been reported in this release.

|

| Drill sample recovery |

- Method of recording and assessing core and chip sample recoveries and results assessed.

- Measures taken to maximise sample recovery and ensure representative nature of the samples.

- Whether a relationship exists between sample recovery and grade and whether sample bias may have occurred due to preferential loss/gain of fine/coarse material.

|

- No drilling has been reported in this release.

|

| Logging |

- Whether core and chip samples have been geologically and geotechnically logged to a level of detail to support appropriate Mineral Resource estimation, mining studies and metallurgical studies.

- Whether logging is qualitative or quantitative in nature. Core (or costean, channel, etc) photography.

- The total length and percentage of the relevant intersections logged.

|

- No drilling has been reported in this release.

|

| Sub-sampling techniques and sample preparation |

- If core, whether cut or sawn and sampling techniques and sample preparation whether quarter, half or all core taken.

- If non-core, whether riffled, tube sampled, rotary split, etc and whether sampled wet or dry.

- For all sample types, the nature, quality and appropriateness of the sample preparation technique.

- Quality control procedures adopted for all sub-sampling stages to maximise representivity of samples.

- Measures taken to ensure that the sampling is representative of the insitu material collected, including for instance results for field duplicate/second-half sampling.

- Whether sample sizes are appropriate to the grain size of the material being sampled.

|

- Rock chip sample weight was between 3 and 5kg per site.

- No standard samples were submitted with the rock chip samples.

|

| Quality of assay data and laboratory tests |

- The nature, quality and appropriateness of the assaying and laboratory procedures used and whether the technique is considered partial or total.

- For geophysical tools, spectrometers, handheld XRF instruments, etc, the parameters used in determining the analysis including instrument make and model, reading times, calibrations factors applied and their derivation, etc.

- Nature of quality control procedures adopted (eg standards, blanks, duplicates, external laboratory checks) and whether acceptable levels of accuracy (ie lack of bias) and precision have been established.

|

- Samples were analysed by ALS for a range of elements by ICP (OES or MS) after an aqua regia or four-acid digest. Gold was analysed via flame AAS.

- The analytical method is appropriate for reconnaissance rock chip sampling.

|

| Verification of sampling and assaying |

- The verification of significant intersections by either independent or alternative company personnel.

- The use of twinned holes.

- Documentation of primary data, data entry procedures, data verification, data storage (physical and electronic) protocols.

- Discuss any adjustment to assay data.

|

- All assays have been verified by alternate company personnel.

- Assay files were received electronically from the laboratory.

|

| Location of data points |

- Accuracy and quality of surveys used to locate drill holes (collar and down-hole surveys), trenches, mine workings and other locations used in Mineral Resource estimation.

- Specification of the grid system used.

- Quality and adequacy of topographic control.

|

- Datum used is UTM GDA 94 Zone 54.

- Rock Chip sample locations are captured via GPS.

- RL information will merged at a later date utilising the most accurately available elevation data.

|

| Data spacing and distribution |

- Data spacing for reporting of Exploration Results.

- Whether the data spacing and distribution is sufficient to establish the degree of geological and grade continuity appropriate for the Mineral Resource and Ore Reserve estimation procedure(s) and classifications applied.

- Whether sample compositing has been applied.

|

- Sample spacing is related to mineral occurrence therefore the sample spacing, and sampling methodology is not sufficient to establish grade continuity.

- The sampling was conducted to define the structure location and relative metal tenor of key elements such as gold, copper, cobalt and silver.

- No compositing has been applied to the assay results.

|

| Orientation of data in relation to geological structure |

- Whether the orientation of sampling achieves unbiased sampling of possible structures and the extent to which this is known, considering the deposit type.

- If the relationship between the drilling orientation and the orientation of key mineralised structures is considered to have introduced a sampling bias, this should be assessed and reported if material.

|

- Sampling is conducted at right angles to the strike of the host structure.

|

| Sample security |

- The measures taken to ensure sample security.

|

- Pre-numbered bags were used, and samples were transported to ALS laboratory in Mt Isa by company personnel.

|

| Audits or reviews |

- The results of any audits or reviews of sampling techniques and data.

|

- The dataset associated with this sampling has been subject to data import validation.

- All assay data has been reviewed by two company personnel.

|

Section 2 Reporting of Exploration Results

(Criteria listed in the preceding section also apply to this section.)

| Criteria |

JORC Code explanation |

Commentary |

| Mineral tenement and land tenure status |

- Type, reference name/number, location and ownership including agreements or material issues with third parties such as joint ventures, partnerships, overriding royalties, native title interests, historical sites, wilderness or national park and environmental settings.

- The security of the tenure held at the time of reporting along with any known impediments to obtaining a licence to operate in the area.

|

- The Toby and Charlie Prospects are located on EPM14232 held 100% by Mt Dockerell Mining Pty Ltd – a 100% owned subsidiary of Hammer Metals Limited.

|

| Exploration done by other parties |

- Acknowledgment and appraisal of exploration by other parties.

|

- The Toby and Charlie Prospects

have not been appraised by other

parties.

|

| Geology |

- Deposit type, geological setting and style of mineralisation.

|

- Mineralisation at Toby is associated

with shear zones with marginal

magnetite and Hematite Breccia

zones. The host at Toby is red rock

altered calc silicates.

- The host at Charlie is brecciated calcsilicates of the Corella Formation. The nature of mineralisation is not yet known.

|

| Drill hole Information |

- A summary of all information material to the understanding of the exploration results including a tabulation of the following information for all Material drill holes:

- easting and northing of the drill hole collar

- elevation or RL (Reduced Level – elevation above sea level in metres) of the drill hole collar

- dip and azimuth of the hole

- down hole length and interception depth

- hole length.

- If the exclusion of this information is justified on the basis that the information is not Material and this exclusion does not detract from the understanding of the report, the Competent Person should clearly explain why this is the case.

|

- No drilling has been reported in this release.

|

| Data aggregation methods |

- In reporting Exploration Results, weighting averaging techniques, maximum and/or minimum grade truncations (eg cutting of high grades) and cut-off grades are usually Material and should be stated.

- Where aggregate intercepts incorporate short lengths of high grade results and longer lengths of low grade results, the procedure used for such aggregation should be stated and some typical examples of such aggregations should be shown in detail.

- The assumptions used for any reporting of metal equivalent values should be clearly stated.

|

- No drilling has been reported in this

release.

|

| Relationship between mineralisation widths and intercept lengths |

- These relationships are particularly important in the reporting of Exploration Results.

- If the geometry of the mineralisation with respect to the drill hole angle is known, its nature should be reported.

- If it is not known and only the down hole lengths are reported, there should be a clear statement to this effect (eg ‘down hole length, true width not known’).

|

- Surface grab sampling cannot be utilised to determine the geometry of any possible mineralisation at depth.

- The sampling methodology can only be used to determine a range of possible grades and is commonly used at a reconnaissance stage.

|

| Diagrams |

- Appropriate maps and sections (with scales) and tabulations of intercepts should be included for any significant discovery being reported These should include, but not be limited to a plan view of drill hole collar locations and appropriate sectional views.

|

|

| Balanced reporting |

- Where comprehensive reporting of all Exploration Results is not practicable, representative reporting of both low and high grades and/or widths should be practiced to avoid misleading reporting of Exploration Results.

|

- All sampling conducted by Hammer

Metals Limited is depicted on the

attached figures and tables.

|

| Other substantive exploration data |

- Other exploration data, if meaningful and material, should be reported including (but not limited to): geological observations; geophysical survey results; geochemical survey results; bulk samples – size and method of treatment; metallurgical test results; bulk density, groundwater, geotechnical and rock characteristics; potential deleterious or contaminating substances.

|

- The Toby Prospect figure shows contours and modelled plates derived from a 2016 VTEM survey conducted by Hammer Metals. The details of this survey were made available to the market on December 22nd, 2016.

|

| Further work |

- The nature and scale of planned further work (eg tests for lateral extensions or depth extensions or large-scale step-out drilling).

- Diagrams clearly highlighting the areas of possible extensions, including the main geological interpretations and future drilling areas, provided this information is not commercially sensitive.

|

- Drillhole planning is underway. First pass RC drilling is planned for early 2019.

|

For the full press release click here (PDF).