Published: August 16, 2018

HIGHLIGHTS

- Reconnaissance mapping and sampling in Bryah Basin identifies highgrade manganese at a new prospect named Brumby Creek.

- High-grade manganese recorded in 19 rock chip samples:

- 5 samples recorded +40% Mn with a highest value of 48.5% Mn, &

- 12 samples recorded 30% – 40% Mn.

- Outcropping manganese mineralisation at Brumby Creek has been mapped over a 2 kilometre strike length.

- Wide zone of outcropping manganese mapped (over 100 metres wide and 250 metres long), representing an outstanding untested drill target.

- Drilling at Brumby Creek Manganese Prospect to commence following final works approvals and site clearances

Bryah Resources Limited (“Bryah” or “the Company”) is pleased to provide an update on manganese exploration activities within its Bryah Basin Project in central Western Australia.

In March 2018, the Company announced the expansion of its Bryah Basin Project exploration programme to include manganese. Since then an extensive programme of ground reconnaissance work has been undertaken with the aim of identifying manganese outcrops and generating targets for follow-up exploration and drilling.

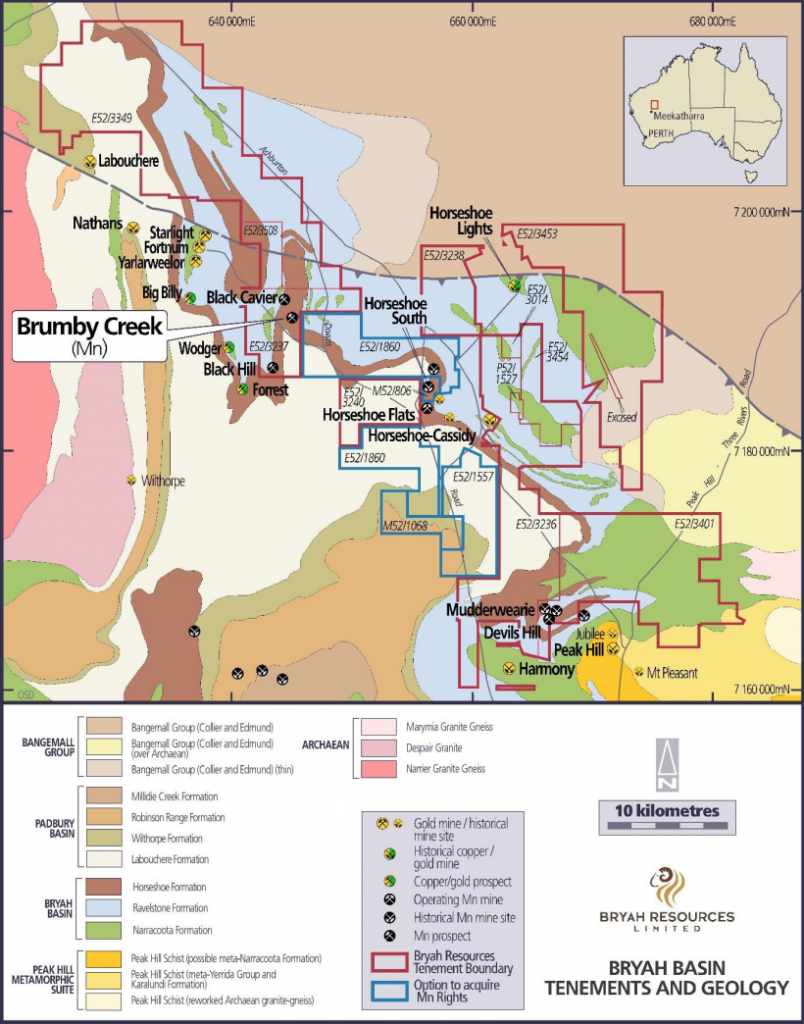

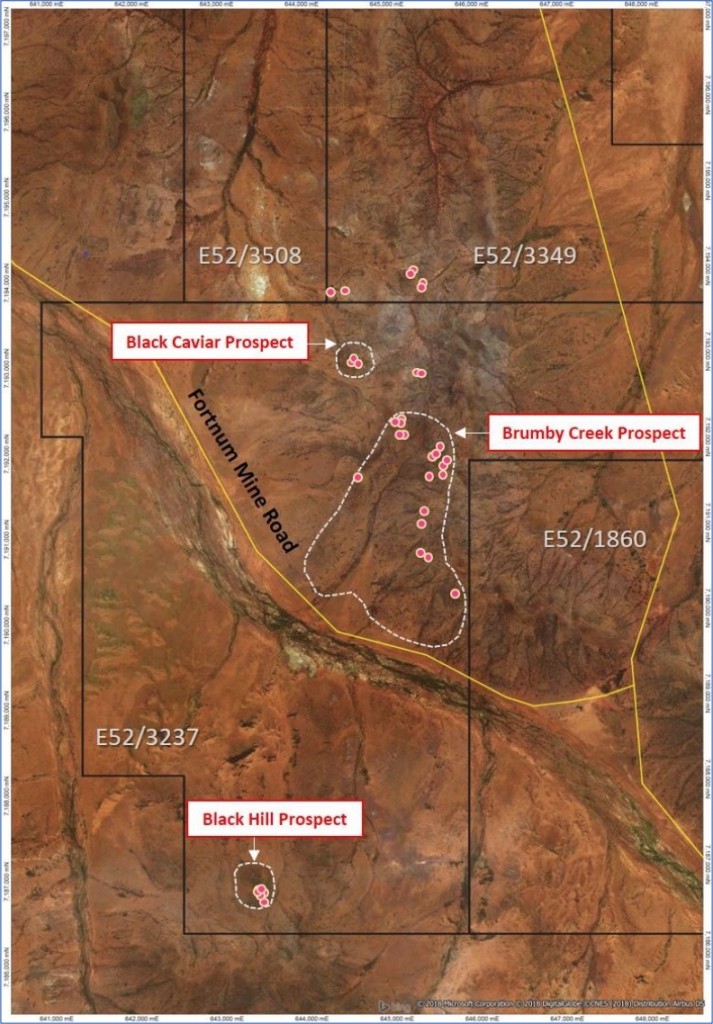

In July 2018, reconnaissance mapping focussed on an area of interest identified from satellite imagery and the recently completed airborne electromagnetic survey. Significant zones of outcropping manganese were identified in this area, which has been named Brumby Creek. The Brumby Creek prospect lies close to the Black Hill and Black Caviar prospects, where previously reported rock chips recorded grades of up to 50% Mn (see Figures 1 and 2).

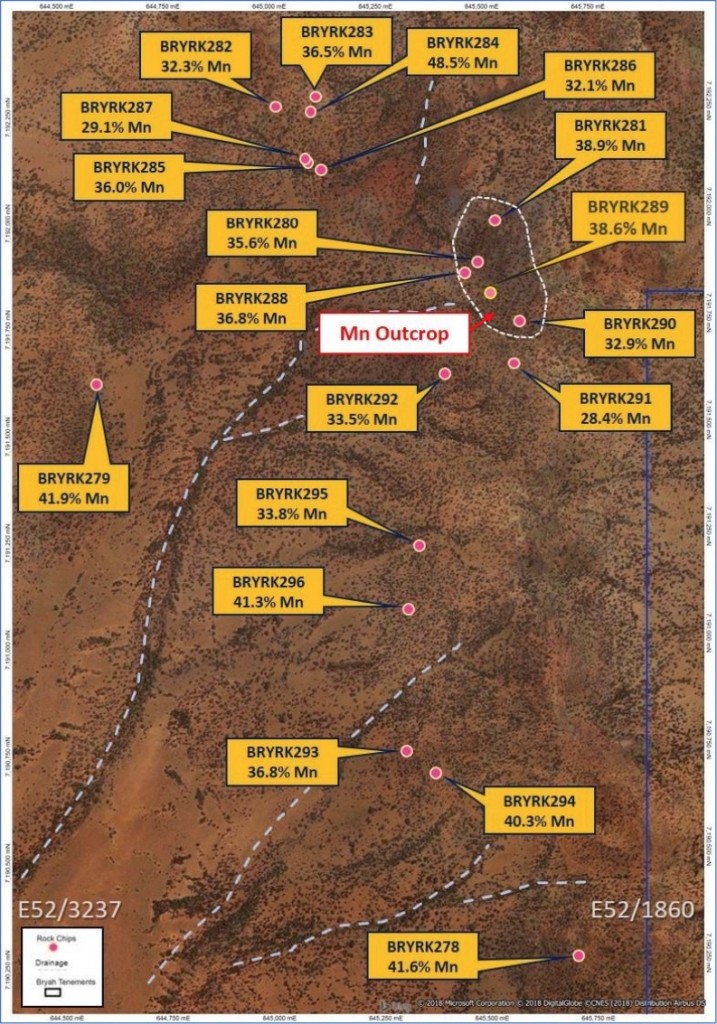

A total of 19 rock chip samples were collected from manganiferous outcrops at the Brumby Creek prospect and laboratory results from these rock chip samples have now been received. Assay results for these samples are shown in Table 1 and in Figures 3 and 4.

Of the 19 rock chip samples, 5 samples assayed above 40% Mn, including a highest value of 48.5% Mn. A further 12 samples assayed between 30% and 40% Mn. The persistent highgrade manganese recorded in these samples is very encouraging.

Figure 2 – Satellite imagery showing Brumby Creek and other nearby Prospects and rock chip sample points

Local Geology

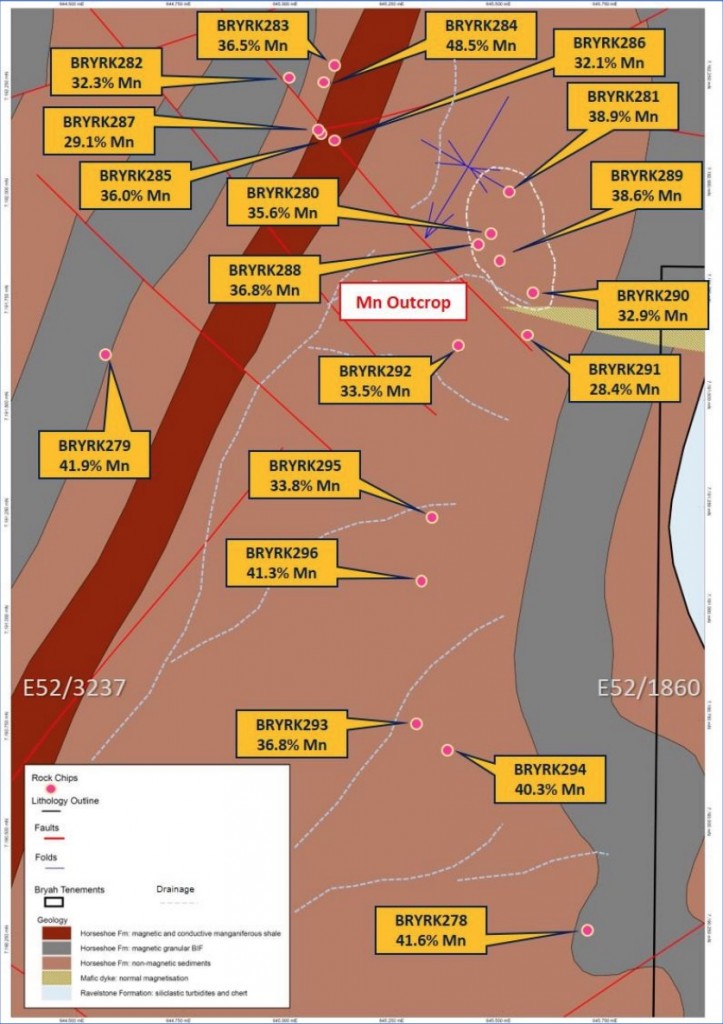

The Brumby Creek Prospect lies within the Horseshoe Formation.

The Horseshoe Formation includes finely laminated ferruginous (hematitic) shale and siltstone, fine-grained quartz–feldspar wacke with interleaved iron formation and chert, graded quartz wacke, manganiferous shale, garnetiferous biotite–chlorite schist and garnetiferous iron-formation. Relatively high manganese contents are inferred from the abundant manganese oxide staining in weathered and lateritic rocks, and lateritic manganese ore has been mined at the Horseshoe South and Mount Padbury mines.1

Structurally, the Horseshoe Formation in this area forms a broad syncline with its axis trending approximately southerly. Recent geophysical interpretation by Resources Potential Pty Ltd has identified a magnetic and conductive manganiferous shale unit, which is co-incident with some of the manganese outcrops sampled, including the highest recorded assay of 48.5% Mn (sample BRYRK284) (see Figure 4).

Manganese outcrops have been mapped over a strike length of 2 kilometres from BRYRK278 to BRYRK281 along the western and southern slopes of, and parallel to, the top of the Horseshoe Range.

Coincidently, the largest area of outcropping manganese identified to date by the Company occurs at the northern end of this 2 kilometres strike and covers an area over 100 metres wide and 250 metres long (see Figures 2-5 and Plate 1). This area of outcropping manganese represents an outstanding untested drill target.

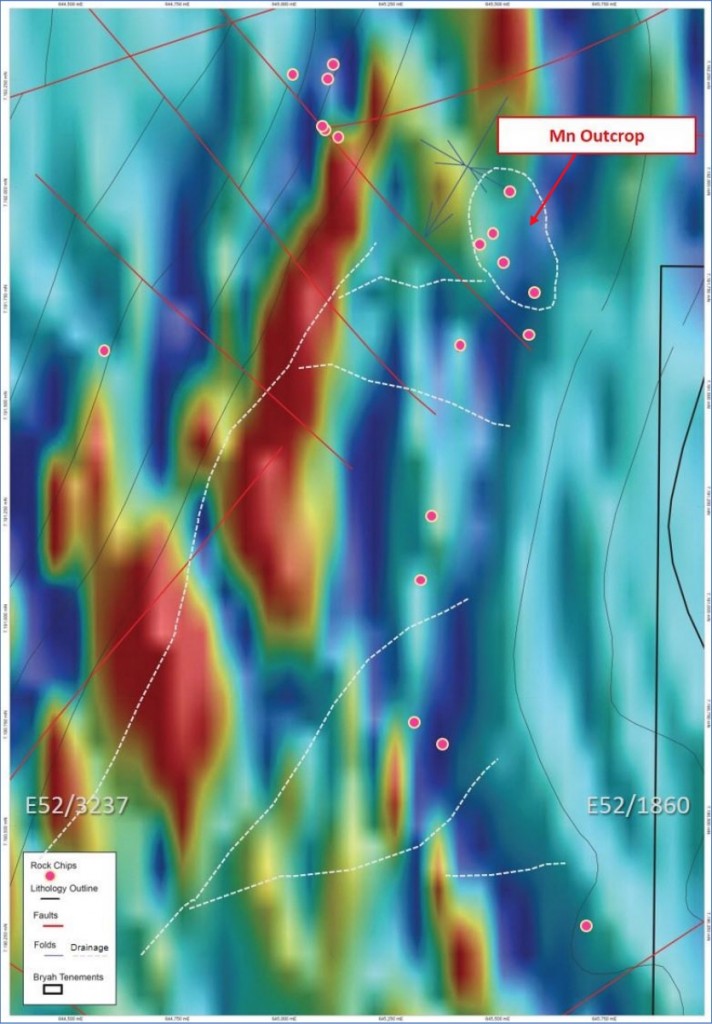

VTEM Survey

The recently completed airborne Versatile Time-domain Electromagnetic (VTEM) survey has identified a significant area with a conductive anomaly response at the Brumby Creek Prospect. The conductive anomaly appears to lie along the axis of the Horseshoe Formation syncline, adjacent to the manganiferous shale unit and generally coincides with the alignment of the creek at the base of a broad valley (see Figure 5).

The conductive zone is interpreted to be caused by geologically young scree deposits, which have potential for containing detrital manganese style mineralisation down slope from outcropping manganese occurrences and sits along the edge of a more conductive paleochannel to the west.

A drilling programme to test this conductive anomaly has been approved by the Department of Mines, Industry Regulation and Safety (DMIRS).

Plate 1 – L-R – Neil Marston (Managing Director) with Geologists David Thompson and Lindsay Bonnett on outcropping high-grade manganese at the Brumby Creek Prospect (vicinity sample BRYRK281).

Commenting on the latest results, Managing Director Neil Marston said:

“We are very excited with the latest results from this ground reconnaissance work, which highlights the benefits of having geologists methodically walking the ground and sampling. The scale and manganese grades recorded from the Brumby Creek Prospect are outstanding in our opinion, so it will be a priority target for follow-up work including drilling.

We are keen to drill for manganese at Brumby Creek as soon as possible. We also look forward to testing the various other surface targets identified by our geological team with a programme of shallow drill holes in the coming months.”

Follow-up Exploration Activities

DMIRS work approvals and site heritage clearances for drilling of manganese targets, including at Black Hill, Black Caviar, Devils Hill and parts of the Brumby Creek Prospect have now been obtained. Preparation for drilling is underway and will commence once all logistics and contracts have been finalised.

DMIRS work approvals and site heritage clearances for the remaining parts of the Brumby Creek Prospect, including the main manganese outcrop is underway. Drilling activities will commence as soon as practicable after access approvals are obtained for these areas.

For Further Information, please contact

Neil Marston

Managing Director

Tel: +618 9321 0001

Table 1 – Bryah Basin Project Manganese Samples – Laboratory Results

| Sample ID | Northing mN | Easting mE | Mn % | Fe % | Al2O3 % | SiO2 % | P % |

|---|---|---|---|---|---|---|---|

| BRYRK278 | 7190258 | 645696 | 41.60 | 8.11 | 7.69 | 5.39 | 0.07 |

| BRYRK279 | 7191611 | 644567 | 41.93 | 9.27 | 7.13 | 4.7 | 0.04 |

| BRYRK280 | 7191889 | 645480 | 35.60 | 11.21 | 10.63 | 7.38 | 0.06 |

| BRYRK281 | 7191981 | 645520 | 38.85 | 7.85 | 9.76 | 7.63 | 0.04 |

| BRYRK282 | 7192260 | 645007 | 32.25 | 20.31 | 5.39 | 4.51 | 0.15 |

| BRYRK283 | 7192284 | 645100 | 36.52 | 13.34 | 7.75 | 5.68 | 0.11 |

| BRYRK284 | 7192245 | 645090 | 48.52 | 6.75 | 3.66 | 2.07 | 0.09 |

| BRYRK285 | 7192125 | 645078 | 36.04 | 14.47 | 8.29 | 4.49 | 0.12 |

| BRYRK286 | 7192113 | 645107 | 32.09 | 19.79 | 6.51 | 3.51 | 0.12 |

| BRYRK287 | 7192129 | 645078 | 29.11 | 23.19 | 6.66 | 3.45 | 0.18 |

| BRYRK288 | 7191858 | 645442 | 39.46 | 8.52 | 8.65 | 7.05 | 0.02 |

| BRYRK289 | 7191817 | 645495 | 38.60 | 15.89 | 4.12 | 3.53 | 0.10 |

| BRYRK290 | 7191746 | 645571 | 32.90 | 18.49 | 6.57 | 3.89 | 0.08 |

| BRYRK291 | 7191653 | 645559 | 28.41 | 18.45 | 4.65 | 14.59 | 0.18 |

| BRYRK292 | 7191619 | 645398 | 33.46 | 18.63 | 6.95 | 3.09 | 0.22 |

| BRYRK293 | 7190738 | 645293 | 36.81 | 14.70 | 6.98 | 3.38 | 0.09 |

| BRYRK294 | 7190685 | 645363 | 40.32 | 12.09 | 6.1 | 3.46 | 0.10 |

| BRYRK295 | 7191225 | 645329 | 33.83 | 20.42 | 3.98 | 3.44 | 0.24 |

| BRYRK296 | 7191070 | 645304 | 41.34 | 10.37 | 5.83 | 4.41 | 0.16 |

About Bryah Resources Limited

In October 2017 Bryah Resources Limited was admitted to the official list on the Australian Securities Exchange (ASX). The Company is a copper-gold-manganese focused explorer with 2 projects located in central Western Australia, being the 720 km2 Bryah Basin Project and the 202km2 Gabanintha Project. In addition, the Company holds a one year option to acquire the historic Horseshoe South Manganese Mine and the Manganese mineral rights over a further 154km2 of ground in the Bryah Basin.

The Bryah Basin is host to the high-grade copper-gold mines at DeGrussa, discovered by Sandfire Resources NL in 2009, and at Horseshoe Lights, which was mined up until 1994. The Bryah Basin also has several historical and current manganese mines.

Bryah Resources Limited’s copper-gold exploration strategy is:

- to apply the best and latest exploration methods to evaluate the ground;

- to use high resolution geophysics to identify deeper structures and potentially mineralised zones, and

- to drill test targets below the depth of previous drilling.

At Gabanintha, Bryah holds the rights to all minerals except Vanadium/Uranium/Cobalt/Chromium/ Titanium/Lithium/Tantalum/Manganese & Iron Ore (Excluded Minerals). Australian Vanadium Limited retains 100% rights in the Excluded Minerals on the Gabanintha Project.

Competent Persons Statement

The information in this announcement that relates to Exploration Results is based on information compiled by Mr Rohan Williams, who is a Member of the Australasian Institute of Mining and Metallurgy. Mr Williams is an employee of Bryah Resources Limited (“the Company”). Rohan Williams has sufficient experience which is relevant to the style of mineralisation and type of deposit under consideration and to the activity which he is undertaking to qualify as a Competent Person as defined in the 2012 Edition of the ‘Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves’. Rohan Williams consents to the inclusion in this announcement of the matters based on his information in the form and context in which it appears.

Forward Looking Statements

This report may contain certain “forward-looking statements” which may not have been based solely on historical facts, but rather may be based on the Company’s current expectations about future events and results. Where the Company expresses or implies an expectation or belief as to future events or results, such expectation or belief is expressed in good faith and believed to have a reasonable basis. However, forward looking statements are subject to risks, uncertainties, assumptions and other factors which could cause actual results to differ materially from future results expressed, projected or implied by such forward-looking statements. Readers should not place undue reliance on forward looking information. The Company does not undertake any obligation to release publicly any revisions to any “forward looking statement” to reflect events or circumstances after the date of this report, or to reflect the occurrence of unanticipated events, except as may be required under applicable securities laws.

Manganese Exploration and Sampling

JORC Code, 2012 Edition – Table 1 Exploration Results

Section 1 Sampling Techniques and Data

| Criteria | JORC Code explanation | Commentary |

|---|---|---|

| Sampling techniques |

|

|

| Drilling techniques |

|

|

| Drill sample recovery |

|

|

| Logging |

|

|

| Sub-sampling techniques and sample preparation |

|

|

| Quality of assay data and laboratory tests |

|

|

| Verification of sampling and assaying |

|

|

| Location of data points |

|

|

| Data spacing and distribution |

|

|

| Orientation of data in relation to geological structure |

|

|

| Sample security |

|

|

| Audits or reviews |

|

|

Section 2 Reporting of Exploration Results

(Criteria listed in the preceding section also apply to this section.)

| Criteria | JORC Code explanation | Commentary |

|---|---|---|

| Mineral tenement and land tenure status |

|

|

| Exploration done by other parties |

|

|

| Geology |

|

|

| Drill hole Information |

|

|

| Data aggregation methods |

|

|

| Relationship between mineralisation widths and intercept lengths |

|

|

| Diagrams |

|

|

| Balanced reporting |

|

|

| Other substantive exploration data |

|

|

| Further work |

|

|

1 GSWA Report 59 – Geology and Mineralization of the Palaeoproterozoic Bryah and Padbury Basins Western Australia, by F. Pirajno, S. A. Occhipinti, and C. P. Swager, 2000

For the full press release click here.